Read More...

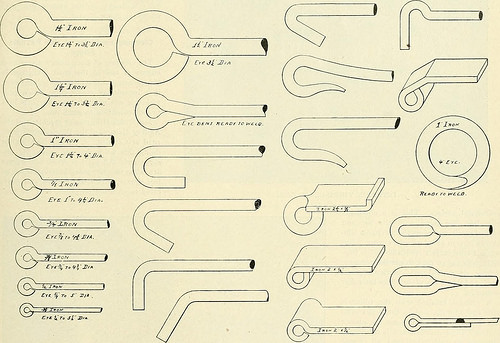

The Aluminium Holding Furnace is designed in such a way that it can serve various purposes. The Aluminium Holding Furnace consists of various metals like Fe, Al, Cr and other metals and various other equipments that support for better distribution of heat and longer service life time of the Aluminium Holding Furnace. These Aluminium Holding Furnaces are well insulted and are capable of melting any type of alloy. The proper insulation of the Aluminium Holding Furnace helps in the better distribution of the heat and energy and this improves the crucible life expectancy. We can find the Aluminium Holding Furnaces in the market available in various sizes and capacities.

Aluminium is the third most common element that we can find in the earth’s crust. The aluminium being so common also is not found in its pure form but is find in combination of other metals with which it forms the ores. You can find aluminium mostly in combination of sulphur and silicon. Aluminium has to be separated from these elements to be used as the purest form for various industrial applications. A study reveals that more than ten billion pounds of aluminium are produced annually across the globe. The ore that contains aluminium is the bauxite ore and it comprises of 60% of bauxite only. The major portion of the bauxite is found in Australia where we can find almost one third of the world’s bauxite in massive open-pit bauxite mines with other and minor portions of the bauxite found in the rest of the world.

The Bauxite ore if mined from the bauxite mines after which it is mixed in sodium hydroxide solution and ground into fine powder. The resulting mixture is then mixed with water and heated to more than 500 degrees Fahrenheit and under a pressure of 50 pounds for square inch. The bauxite is kept in such condition for several hours while the sodium hydroxide eats away all the aluminium compounds by dissolving them. This resulted mixture is then taken to a holding tank where the non-aluminium solids settle at the bottom of the tank. Now as we have seen that the aluminium compounds have been completely dissolved into the sodium hydroxides solution, this can be easily pumped through a filtration system.

There are then progressively finer filters that catch and stop back if impurities are present. The aluminium rich chemical is then moved to another aluminium holding tank where the aluminium crystals are placed on top of the liquid. These aluminium crystals keep on increasing in the size as they keep on adding the aluminium particles to them. The resulting solution is pumped into an kiln where the liquid is evaporated leaving behind the pure aluminium crystals. The aluminium crystals are then cooled and these must undergo smelting process once to form the purest form of aluminium.

Finally the Hall-Heroult process is the smelting process that gives us the purest form of aluminium which is then given to the manufacturers who use this pure aluminium for their own manufacturing.

Related Posts

-

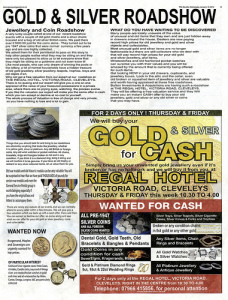

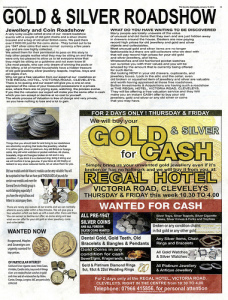

Turn Your Scrap Gold Into Money

A highly valuable and precious metal, Gold has a lot of utilities other than

Turn Your Scrap Gold Into Money

A highly valuable and precious metal, Gold has a lot of utilities other than -

Cash For Gold

Do you have what it takes to transform carats into liquid assets? Gold dealers

Cash For Gold

Do you have what it takes to transform carats into liquid assets? Gold dealers -

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to -

Get The Best Price For Your Scrap Gold

The price of gold goes up when the demand for it is high. You

Get The Best Price For Your Scrap Gold

The price of gold goes up when the demand for it is high. You -

What is Scrap Gold? How To Fruitfully Market This Material

Most people are not conscious that one of the most engrossing areas of bullion

What is Scrap Gold? How To Fruitfully Market This Material

Most people are not conscious that one of the most engrossing areas of bullion -

How to sell Scrap Gold to get the maximum benefit?

Gold is a precious metal and getting tremendous importance from ancient time. Gold purchase

How to sell Scrap Gold to get the maximum benefit?

Gold is a precious metal and getting tremendous importance from ancient time. Gold purchase -

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to -

Portland Gold Buyers Commodity

To sell gold to Portland gold buyers a person must understand how the system

Portland Gold Buyers Commodity

To sell gold to Portland gold buyers a person must understand how the system