Read More...

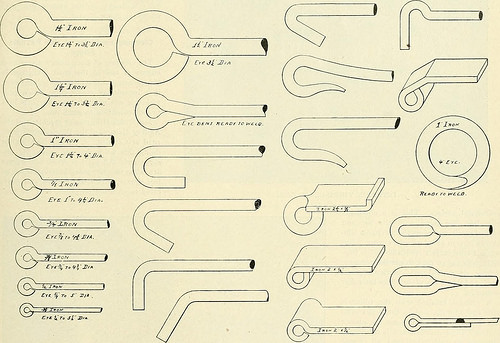

One of the forms of extracting metals is smelting. The purpose of the smelting process is to produce a metal from its original ore. This includes many types of base metals such as extracting iron from iron ore and copper from its ore. The process of smelting uses both heat and a chemical reduction agent. This process changes the oxidation state of the ore.

Typical reduction agents are made of some type of carbon, such as coke or charcoal. The carbon works to remove the oxygen from the ore and leaves behind the metal. There are two stages of oxidization of carbon, the first produces carbon monoxide and the second produces carbon dioxide.

Smelting Process

Essentially, smelting may seem like it is just simply melting the ore to get to the metal. However, the process is a bit more complex than this. Ores are typically part of a chemical compound that includes the metal along with several other elements, including sulfide, oxides, and carbonates created by carbon and oxygen. In order for the metal to be released a chemical reaction must occur within these compounds. For this reason, the smelting process must include some type of reducing substance that will combine with the elements in order to free the metal.

Roasting Process

For sulfides and carbonates, a roasting process is used to get rid of the unwanted sulfur or carbon. This will leave the oxide behind that can then directly be reduced. Typically, this process is carried out in some form of oxidizing environment.

Examples of roasting include Malachite, which is one of copper’s common ores. It is made of mostly copper carbonate, which will undergo thermal decomposition at the temperatures between 250 and 350 degrees Celsius. The carbon dioxide will be expelled, which leaves behind the copper oxide. This can be reduced to copper.

Reduction

The final high temperature step in the smelting process is reduction. This is where the final oxygen is taken from the raw metal and the elemental metal is released. The temperature required for this process will vary depending on what the melting point of the base metal is.

Fluxes

In the smelting process, fluxes are used to serve many purposes. The main purpose of fluxes is to catalyze the reactions and to be chemically binding to the unwanted reaction products and impurities. One of the most commonly used oxides for this process was calcium oxide, which is used in the form of lime. This is because would react with the sulfur dioxide and carbon dioxide during the roasting process and keep it out of the work environment.

Common Metals

There are several types of metals that can be removed from their ore using the smelting process. The most commonly known metal that the smelting process is used for is iron. However, smelting can also be used for removing tin, lead, copper, bronze, and aluminum from their ores as well as several other types of metals such as zinc.

To find out more about smelting and general mining topics, please visit PublicMining.org, a free resource directory showcasing public mining companies like Win-Eldrich Mines, Creso Exploration and thousands more.

Related Posts

-

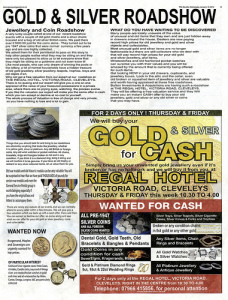

Turn Your Scrap Gold Into Money

A highly valuable and precious metal, Gold has a lot of utilities other than

Turn Your Scrap Gold Into Money

A highly valuable and precious metal, Gold has a lot of utilities other than -

Cash For Gold

Do you have what it takes to transform carats into liquid assets? Gold dealers

Cash For Gold

Do you have what it takes to transform carats into liquid assets? Gold dealers -

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to -

Get The Best Price For Your Scrap Gold

The price of gold goes up when the demand for it is high. You

Get The Best Price For Your Scrap Gold

The price of gold goes up when the demand for it is high. You -

What is Scrap Gold? How To Fruitfully Market This Material

Most people are not conscious that one of the most engrossing areas of bullion

What is Scrap Gold? How To Fruitfully Market This Material

Most people are not conscious that one of the most engrossing areas of bullion -

How to sell Scrap Gold to get the maximum benefit?

Gold is a precious metal and getting tremendous importance from ancient time. Gold purchase

How to sell Scrap Gold to get the maximum benefit?

Gold is a precious metal and getting tremendous importance from ancient time. Gold purchase -

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to

Scrap Gold Buyers – An Overview

With the global financial crisis hovering over, people are looking for many ways to -

Portland Gold Buyers Commodity

To sell gold to Portland gold buyers a person must understand how the system

Portland Gold Buyers Commodity

To sell gold to Portland gold buyers a person must understand how the system